At the start of March our church asked if I could take a look at some communion tables that were a little wobbly. They were purchased tables and are often moved around during the week. Over the years the legs had been bumped around and were slightly unstable.

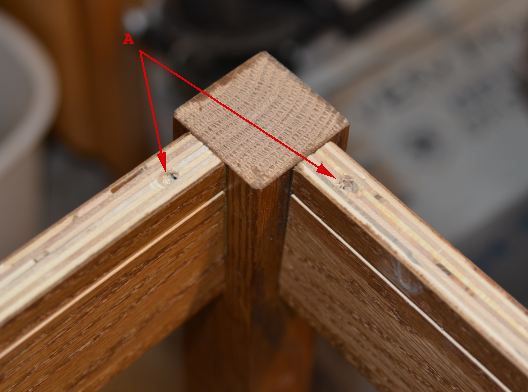

The tables were created with solid oak legs, solid oak top, but the rails where made of plywood. I’m not sure why they used plywood, maybe for uniformity of appearance. These were attached to the legs using a non-reinforced butt-joint, with screws from the top and bottom (A).

Butt-Joints with screws (A)

Over time the glue of the butt joints gave way to strain of being moved over and over again. This left the screws as being the only thing holding the tables together, and in taking the full strain of that responsibility they began to split the plywood:

Original construction showing the plywood splitting

It looked like they’d been repaired a few times, reglued, sometimes with wedges and with some additional screws.

Original repair to be removed, wood wedges, glue, some wood filler material.

These held for a while, but couldn’t withstand the long term wear and tear. The tables needed an overhaul. The idea though was to save as much of the original table as possible, and hopefully only refinish parts of them and not the entire table. At first glance this would include replacing some of the rails, but after tearing the tables down to their components it was clear that every rail should be replaced. The top of the tables were in very good condition, the legs were in good condition, but the rails were a loss.

So, first decision was to use solid oak for the rails, not plywood. The original rails were a slightly differnt color then the top and legs, probably because they were plywood and the stain didn’t take as well. Using solid oak, albeit new wood, was going to be easier to match and control the stain and would provide good solid support.

Next was to find a matching stain, after talking to a few people familiar with the person who had repaired them in the past, and trying a few out, a variation of Golden Oak (B) seemed to work best

Disassembled parts and the stain match (B)

Next the legs were cleaned up, removing the wood filler, the old glue, screws, etc.

New Rail Structure

After the legs were prepared, it’s time to decide how to restructure the table. You have a lot of options in building a table, reinforced butt joints with dowels, mortise and tenon, steel corner brackets, pocket screw joinery, etc… I wanted something strong, but make sure it was likely I’d get it done in a good timeframe and not make a significant mistake. Normally I’d do a mortise and tenon joint on tables, but after some debate I decided to go pocket screw joinery. This in conjunction with the solid oak wood should be a good fit for this usage.

Each original rail had a piece of oak trim as a lip on the bottom, which I was able to salvage and re-use. A few of them had to be stripped and refinished

Brand New Rails stained, glued, and pocket-screw joined

I ripped a groove in the top of the rails to connect the top in the same way it originally was.

Brand New Rails stained, glued, and pocket-screw joined

It worked out, I didn’t need to completely refinish each entire table, and after a couple coats of poly on the rails they were done.